Profiling a Gaussian Laser Beam

Ben Coe, Pradyoth Kukkapalli, and Annie Nam

Laser Teaching Center, Stony Brook University

August 2010

Introduction

Many people have the idea that laser beams are perfectly parallel "lines of

light." Initially, we also held this naive belief, but Dr. Noe challenged our

misunderstanding by demonstrating that the beam from a green laser pointer

clearly diverges. But how does the size of the laser beam relate to the

distance to the screen? We hypothesized that the beam width could not be

directly proportional to the distance because if that were true, extrapolating

back to a distance of zero from the laser would produce a beam size of zero,

which just didn’t make sense. We believed that the relationship would be

linear, but rather than being directly proportional the diameter and distance

would be related by an equation of the form ax + b, where a is the rate of

divergence and b is the initial diameter at zero distance.

This mini-project consisted of two parts. First, we looked at how the laser beam

from a green laser pointer diverges with increasing distance. This part of the

experiment was done in the long hallway outside the lab, where we could place the

laser as much as several hundred feet away from the screen. Later we measured the

intensity profile of a red HeNe laser by a much more precise method at distances

that were mostly less than one meter from the laser. Our results showed that the

profile is not linear as we originally expected, but rather is curved. The actual

hyperbolic shape is approximately constant near the laser and diverges in

proportion to distance in the far field, due to diffraction.

Green Laser in the Hallway

Our green laser was held on a small tripod stand that sat on the ground, and was

pointed at the wall at the end of the hallway. Each of us separately visually

estimated the diameter of the laser spot on the wall using a meter stick. We

repeated this procedure at several distances from the wall, from 35 meters (116

feet) up to about 141 meters (480 feet). We used a 25 foot tape measure to make

marks every 25 feet in the hallway to make measuring the distances more

convenient.

We plotted and analyzed our data in a spreadsheet program. We used the Least

Squares Method to determine the slope of the line of form ax + b that best matches

the data. This method works by squaring the difference between each corresponding

theoretical and experimental value. All of these terms are added together to

produce a measure of the total error. By minimizing the total error by changing

the parameters, we could find the curve that best represents the data points.

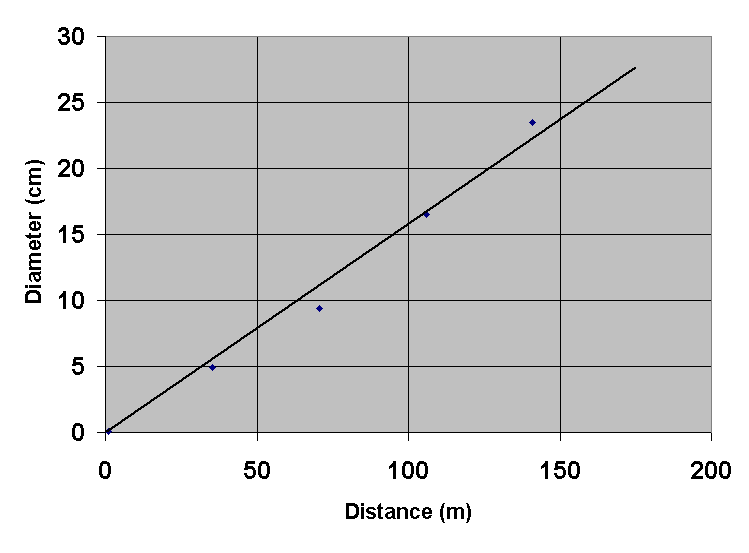

Figure 1. Estimated diameter of the green

laser

pointer beam as a function of distance.

The graph above shows our results. It is apparent from the graph that a line

passing through the origin (b=0) is sufficient to represent the data. We

realized from this initial experiment that we need to measure (profile)

the beam diameter much closer to the laser. The beam is very small there

so a more exact method is needed.

HeNe Laser Experiments

1. Razor blade method

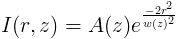

We learned from different sources that the intensity distribution of many

laser beams is given by a Gaussian function -

In this equation r is the distance from the center of the beam and A(z)

and w(z) describes the peak intensity and width of the beam, which both change

with distance z along the beam. I(r) can be measured directly by moving a

pinhole across the beam and recording how much light passes through it, as this past

LTC student did. Unfortunately one needs a very tiny pinhole or narrow

slit to get accurate results where the beam is very small. A better method is

to gradually cut off the beam by moving a razor blade into it, as shown in

this figure.

Figure 2. How a razor blade can "cut" a laser beam.

In this case the changing intensity of the part of the beam that's

not cut off is given by an integral like this, where x is the position of the

blade.

The theoretical curve given by this integral can be matched to the data points

by a least-squares method like we used before. The result is the width w of

the laser beam at some particular distance from the laser.

2. Setup and Procedure

Figure 3 shows our setup. We initially used the same green laser pointer as

before but unfortunately the characteristics of its beam suddenly changed when a

new battery was used, possibly due to damage to its crystal. Therefore we switched

to the very stable red HeNe laser shown. The photodetector was a Thorlabs DET110

whose current was read by a multimeter. We placed a converging lens ahead of the

detector to ensure that none of the beam missed the detector. As shown the

detector was intentionally placed away from the exact focus of the lens to avoid

possibly damaging the detector.

Figure 3a. A bird's eye view of the experimental setup

Figure 3b. A picture of the setup

The razor blade was taped to a right-angle bracket that was attached to a micrometer-driven translation

stage. We moved in steps of either 1 or 2 mils. (One mil equals 0.001 inch or 25.4 microns.) We made

these measurements at 31 different distances under 70 mm and also at 300 mm.

In all, we wrote down and entered over 1000 data points by hand.

In retrospect we took more data

than we needed. Fewer width measurements over more evenly spaced distances would have been sufficient.

3. Analysis and Results

Two types of analysis were done - (a) finding the beam width w(z)

at each of the 32 distances and (b) constructing the beam profile from these

results. Both used the least-squares method that was employed previously

with the green laser pointer data.

When finding the beam width by the least squares method one has the problem

that the theoretical function (integral of a Gaussian) can not be written

as a formula and thus cannot be directly compared to the data. The integral

in fact defines a special function called the "error function," or

erf(x). We dealt with this by numerically integrating the trial Gaussian

functions and comparing these numerical integral curves to the data. The

numerical integral is computed by simply summing all the Gaussian values

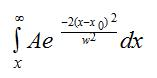

up to some particular point x. The result of one such least squares

analysis is shown in Figure 4.

Figure 4. One of 32 sets of width data with its best-fit erf curve.

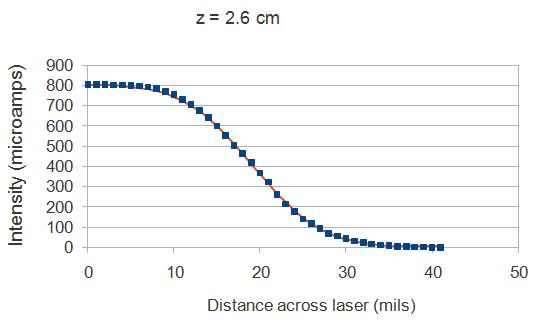

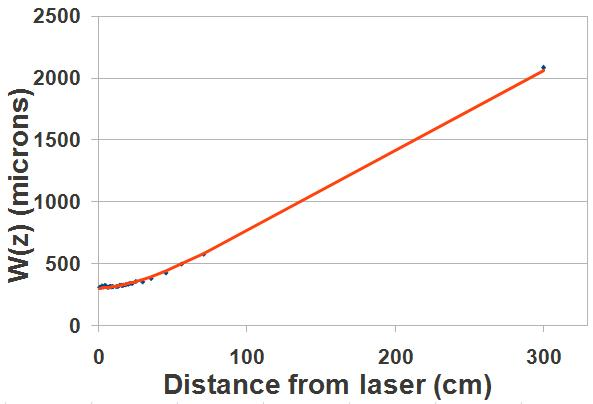

When we plotted the 32 different beam width values, w(z), we found that the

points formed a hyperbola. According to the reference below and others,

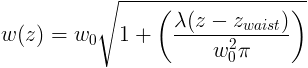

the formula for the hyperbola is

where w0 is the beam width at its minimum value, or "beam

waist," zwaist is the distance of the beam waist from the

face of the laser, and λ is the wavelength of the laser. A positive

zwaist means the waist is in front of the laser's front

face.

Our results are shown in Figure 5.

We found that the waist position was 3.6 cm behind the

front face of the laser, which must therefore be where the

surface of the output coupler mirror is. We also found

w0 = 299.3 microns, which corresponds

to a Rayleigh range [1] of 444 mm.

Figure 5. Measured and best-fit beam profile.

We can determine the length of the laser cavity by finding the beat frequency

between the longitudinal modes of the laser. The equation of beat frequency

is

where c is the speed of light. With help from Vince [link] we found a

beat frequency of 685.81 MHz, which corresponds to L = 21.8 cm. This result

is in reasonable agreement with our conclusion that the waist is 3.6 cm

behind the face of the laser, since the total length of the laser is 27.0 cm.

By finding the divergence of the laser beam, which explains

how the beam diffracts at large distances as the hyperbolic curve

approaches a line, we were able to calculate the wavelength of the laser

beam. The beam's divergence, theta, is described by the equation:

[4] [4]

Equation[4] can be used to find the wavelength of

the laser beam by using the approximate slope of the curve as the

divergence. Using a divergence of 6.568 radians, and a waist size of 299.3

micrometers, we found that the wavelength of the laser was 617.58

nanometers. The error in this calculation is only 2.28 percent, when

compared to the theoretical value of the laser, which was 632

nanometers.

Conclusion

In this project we learned not only about the changing profile and propagation of

a laser beam, we also discovered how to determine the length and mirror

configuration of the laser cavity. Finally, we learned that careful measurements

of the beam profile such as ours can even be used to roughly determine the

wavelength of the laser!

References

[1] Enrique J. Galvez. "Gaussian beams in the optics course." Am. J. Phys.

74, xxx-xxx (2006).

|