Background

Conventional composite membranes currently run into the issue of pore blockage when soaked in amine solutions. The clogged pores create increased coating thickness, which decreases the flux rate. Cellulose is being considered for use in these membranes. It's an abundant, renewable, and cost-effective material; however, it has poor solubility in common organic solvents, limiting its applicability. Despite this, cellulose can offer improved properties due to its chemical stability, environmental affability, and biocompatibility. Previous methods of preparing cellulose membranes have been complex, expensive, and toxic.

Technology

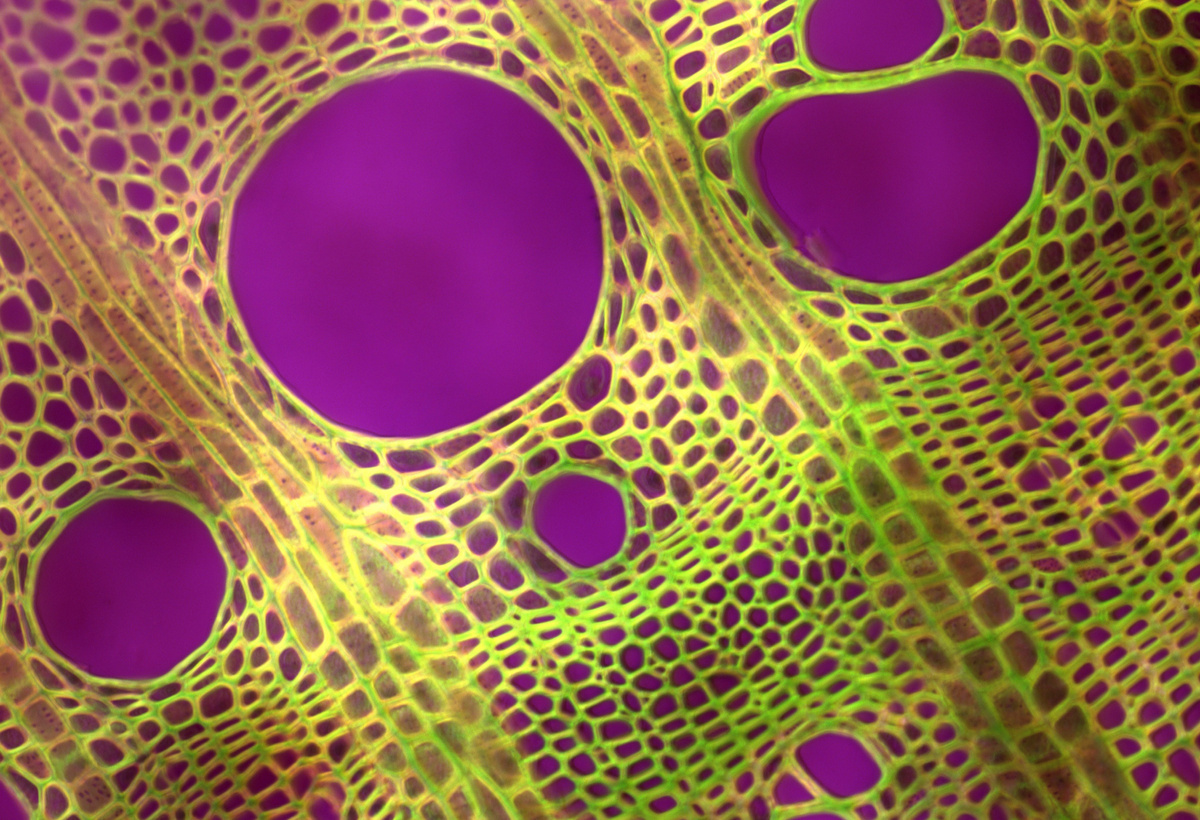

This invention provides a membrane with a cellulose or cellulose derivative coating layer and a porous support comprised of nanofibers. The membrane is prepared by coating a solution with cellulose or a cellulose derivative dissolved in an ionic liquid onto a porous support layer. The ionic liquid is removed, which forms the coating layer. The coating layer has a thickness from around 0.1 to 1 ¼m. The porous support layer containing nanofibers has a core-shell structure, where each piece comprises a different polymer.

Advantages

-Improved water flux and high rejection rates for oil/water emulsions-Cellulose composite membranes provide improved properties and are easily prepared using environmentally friendly solvents

Application

-Fluid separation systems-Ultrafiltration-Nanofiltration-Reverse osmosis-Forward osmosis

Inventors

Benjamin Chu, Distinguished Professor, Chemistry

Benjamin Hsiao, Distinguished Professor, Chemistry

Hongyang Ma, Professor, Chemistry

Licensing Potential

Commercial partner,Development partner,Seeking investment

Licensing Status

Available for licensing.

Licensing Contact

Donna Tumminello, Assistant Director, Intellectual Property Partners, donna.tumminello@stonybrook.edu, 6316324163

Patent Status

Patented

[9010547](https://patents.google.com/patent/US9010547B2/en)

Tech Id

7958