Background

Transportation is one of the major aspects of a society and it is vital for it to function. Current technologies used for transportation, including electric vehicles, consume a significant amount of fossil fuels and produce a substantial amount of CO2 emissions. These emissions contribute to global climate change and can lead to lower air quality.Conventional transportation technologies are not efficient and have a negative impact on the environment. They are not suitable options that can be used for long‑term societal benefit. Therefore there is a need for a new technology in the transportation market that can reduce energy consumption and pollutant emissions.

Technology

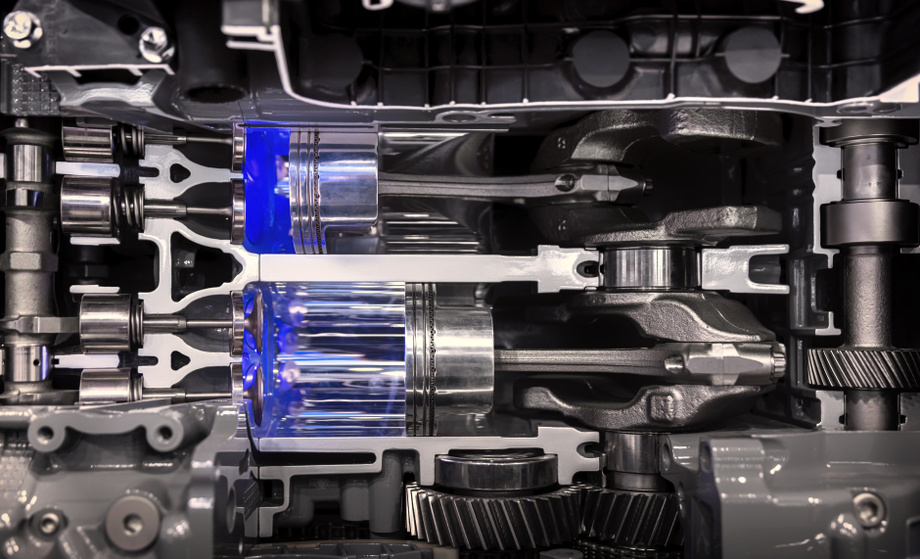

This technology revolves around thermally stratified compression ignition (TSCI) which provides cycle‑to‑cycle control over advanced combustion. There are various methods that can be implemented using TSCI involving single/multiple injection systems. This specific process focuses on the split injection strategy where a portion of the fuel is directly injected during the intake stroke and a portion of the fuel is directly injected during the compression stroke. By controlling the injection timing and the amount of fuel injected, the combustion rate in TSCI can be controlled as well. In the combustion chamber walls, there are fractions of fuel that are evaporated which affect the temperature/combustion rate that needs to be accounted for. There are fractions of fuel evaporated into air and fractions of fuel that evaporate off the chamber walls. As the injected liquid evaporates, it absorbs heat in the phase change to the gaseous state and this depends on whether the evaporation occurs in the air or on the chamber walls. If the evaporation occurs in the air then it decreases the air temperature in the cylinder because it absorbs heat from the incoming air. If the evaporation occurs on the combustion chamber walls, the temperature does not significantly change because the walls have a substantially higher specific heat. By controlling the injection timing, the fraction that evaporates in the air vs the walls can be varied, and therefore the temperature in the cylinder can be controlled on a cycle‑to‑cycle basis. Then, as a result of controlling the temperature, the start of combustion can also be controlled. A water‑fuel mixture works best in this process due to the high heat of vaporization it has.

Advantages

Similar/slightly more efficient than diesel engines (used for heavy-duty application, on-highway trucking, and construction) - Significantly cleaner emissions characteristics than diesel engines - Significantly cheaper than diesel engines - Significantly better control and a larger operating range than other advanced combustion strategies - Can use current production engine hardware without requiring any change to the engine architecture - Can use a domestically mass-produced biofuel and saves energy during the production of the biofuel

Application

This technology can be applied to a multitude of transportation technologies and can be implemented to processes in exchange for diesel/bio/electric processes in transportation vehicles.

Inventors

Benjamin Lawler, Assistant Professor, Mechanical Engineering

Mozhgan Rahimi Boldaji, Graduate Student, Mechanical Engineering

Brian Gainey, Graduate Student, Mechanical Engineering

Licensing Potential

Development partner - Commercial partner - Licensing

Licensing Status

Available for licensing - R# 9103

Licensing Contact

James Martino, Licensing Specialist, Intellectual Property Partners, james.martino@stonybrook.edu,

Patent Status

Provisional patent

https://patents.google.com/patent/US20220316391A1/en?oq=17%2f626%2c222

Tech Id

050-9103