South Fork of Long Island (SFLI) is a high-density residential area facing power shortage in coming years. Due to large summer population, the electricity demand has a distinct seasonal pattern. The annual average power demand is 55 MW, however the summer month demand is 95 MW on average, reaching values as high as 140 MW for 10-20 hrs. In this project CIEES-UTS team is evaluating liquid salt (ZEBRA) batteries as an energy storage solution for South Fork region. ZEBRA batteries offer a low-cost energy storage that is better suited for an area with distinct seasonal energy demand. The battery normally operates at 300oC, when cooled to the ambient temperature it can be stored indefinitely. A battery farm would be activated for summer month only, thus requiring no off-season maintenance.

CIEES Completed Projects

The Center for Integrated Electric Energy Systems has engaged in a variety of energy projects with our industrial partners, including National Grid, Con Edison, Unique Technical Services LLC, ChemCubed LLC, and more.

View our completed projects below.

Principal Investigator: Dr. Fang Luo

Industrial Partner: JetCool LLC

The project develops microconvective liquid cooling technology that uses arrays of fluid jets to cool the industry's highest power devices. Unlike typical heat sinks or cold plates that pass fluid over a surface, our cooling jets route fluid directly at the surface, creating an order-of-magnitude improvement in heat transfer. CIEES assisted the SBU team in setting up the experiment in the Advanced Energy Center.

Principal Investigator: Dr. Fang Luo

Industrial Partner: PowderMet Inc

These projects develop high resistance, high permeability and saturation, low coercivity magnetic cores for power conversion systems. The developed soft magnetic will benefit the current state-of-art of soft magnetic to allow designers to increase system power at high frequency while reducing the weight and size, also reducing (or, in some cases, even eliminating) the need for costly, large, and heavy cooling systems. The CIEES team assisted in calorimetric measurements of the magnetic alloys.

Principal Investigator: Dr. Devinder Mahajan

Industrial Partner: Danskammer Energy

Development of prototype gas negation unit at IGIT facility

Development of prototype gas negation unit at IGIT facilityThe project will realize the integration of the 5kW power demonstration unit. The CIEES team will determine additional markets and demand for Hydrogen supplies in the region/state that could be applicable to all parts of the nation. The team will identify, assess and evaluate the feasibility of Hydrogen suppliers for New York State to deliver fuel to transition from fossil fuels.

Principal Investigator: Dr. Devinder Mahajan

Industrial Partner: Consolidated Edison Company

Hydrogen storage units in Prof. Mahajan's lab

Hydrogen storage units in Prof. Mahajan's labThe project studies the Hydrogen absorption/desorption kinetics in mixed metal hydrides on the Power to Gas unit. It is known that hydrogen storage in metal hydrides is one of the attractive approaches for storing gaseous hydrogen. One attractive class of metal hydride system, mixed metal alloys, shows high hydrogen storage capacity, rapid kinetics and a relatively long electrochemical charge-discharge cycle life. The excellent properties of alloy type hydrides alloys makes them promising for stationary hydrogen storage. CIIES team assisted IGIT in assembly and provided gas analysis equipment.

Principal Investigator: Dr. Simon Marcia

Industrial Partner: MEAN Technology LLCThe CIEES team will perform an environmental assessment of a recycling process for the platinum catalyst contained in the Membrane Electrode Assemblies of a polymer electrolyte membrane fuel cell. During this study, four hydrometallurgical platinum recovery processes from cathode will be analyzed at a laboratory scale.

Principal Investigator: Dr. Devinder Mahajan

Industrial Partner: National Grid

The Institute of Gas Innovation and Technology (I-GIT) is a partnership between Advanced Energy Research and Technology Center (AERTC) and National Grid-USA. The IGIT team will demonstrate a power-to-gas (P2G) concept that will produce Hydrogen, store it in a 14-cylinder metal hydride rack and feed to run a 5kW fuel cell unit. The unit will be sited at AERTC as a demonstration unit to validate the P2G concept. CIEES assisted IGIT in assembly and evaluation of Fe-Ti hydrogen storage units.

Principle Investigator: Dr. Anurag Purwar

Industrial Partner: ThermoLift, Inc.

ThermoLift, based in Stony Brook, NY is developing a cold-climate, natural gas air-conditioner and heat pump technology that combines heating, air-conditioning, and water heating into a single appliance. It can provide a 30-50% reduction in building HVAC costs as well as associated reductions in greenhouse gas emissions. Currently, Thermolift heat pumps are undergoing pilot testing in British Columbia, Canada, by the local utility, Fortis BC. Ten customers, five residential and five small commercial buildings, are testing a new natural gas heat pump technology for space and water heating. The ThermoLift heat pump provides space and water heating in one system and is reported to offer efficiencies as high as 160 percent. This pilot, the first in North America, will test the efficiency, reliability and customer acceptance of the technology. ThermoLift C.E.O., Paul Swartz, credits CIEES for providing expertise and assistance during the critical stages of technology development. The CIEES put together a team of scientists who performed thermodynamic analysis of the ThermoLift engine.

Principle Investigator: Dr. Sergey Suchalkin

Industrial Partner: BAH Holdings LLC

A team of scientists and engineers at Stony Brook University is developing novel mid-IR optical elements for methane sensing. The sensing elements are manufactured by the advanced molecular beam epitaxy and tuned to optical absorption lines of methane. The technology enables sensors with ultra-low power consumption. Such sensors can operate on a single battery for 10 years. The CIEES team assisted BAH in testing the emitter efficiency at high temperatures using the environmental chamber at the Advanced Energy Center.

Optical sensing package designed for BAH Holdings methane sensors by SBU team.

Graduate students of the Electrical Engineering Department testing mid-IR optical elements.

Principle Investigator: Dr. Vyacheslav Solovyov

Industrial Partner: ChemCubed LLC

ChemCubed Scientist

operating an ink-jet printerChemCubed L.L.C. is a small business in the field of flexible electronics that finds multiple uses in energy, aerospace and automotive products. The company utilizes methods of additive manufacturing to manufacture composite materials with precisely controlled properties, such as hardness, tensile strength, elongation at break, Young's modulus, electrical conductivity, thermal conductivity, flame retardancy, security (tagging), or a combination thereof. In various aspects, the methods can include printing amounts of two or more curable liquids from a multichannel piezo head device to form a layer that can be cured by applying a wavelength of light from a light source.

The CIEES team performed mechanical and structural tests of composite samples provided by ChemCubed, currently residing in AERTC, Stony Brook's R&D Park. Flexible electronics is a fast-growing area where Chem Cubed is well-positioned to take a lead. CIEES employed a post-doctoral research associate who performed the sample analysis using the equipment available at CIEES.

Principle Investigator: Dr. Vyacheslav Solovyov

Industrial Partner: StorEn Technologies

SBU interns testing a StorEn batteryStorEn is commercializing the vanadium flow battery (VFB) which is a rechargeable flow battery that employs vanadium ions in different oxidation states to store chemical potential energy. During this period, the CIEES team concluded testing of the unit. The unit was charged up to 100% of the stored energy capacity, 20 kWh, more than 100 times. The CIEES team confirmed the high round trip efficiency and charge retention of the battery. The battery demonstrated stable operation up to the maximum 5 kWh power.

Industrial Partner: ChemCubed, LLC

ChemCubed is developing and manufacturing inks and coatings for flexible electronics and printing.

Composite materials and methods of additive manufacturing are provided for producing the composite materials with precisely-controlled properties. Examples of properties that can be precisely controlled in the composite material can include the hardness, tensile strength, elongation at break, flame retardancy etc. In various aspects the methods can include printing amounts of two or more curable liquids from a multichannel piezo head device to form a layer that can be cured by applying a wavelength of light from a light source. Preparing and testing of these materials are needed for commercialization.

CIEES team works with ChemCubed on evaluation of the advanced composites using the equipment available at the CIEES facility and the Composite Center.

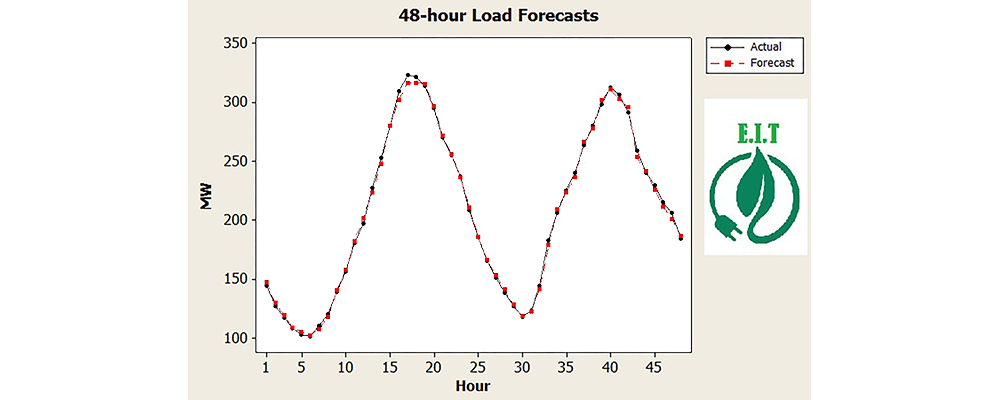

Industrial Partner: Energy IT, Inc

Energy IT is a small business developing predictive digital models for electric grid utilities.

The CIEES team, led by Prof. Eugene Feinberg, is developing a predictive digital model of electric grid.

The team will design and develop a meter and data management system that will be eventually integrated into the larger energy management system. The model will also include medium- and long-term load forecasting features, which use time-series analysis and/or methods of artificial neural networks, and integrate them into the previously developed short-term load forecasting system. During the project the team will also conduct research and development of fast service restoration models and algorithms for electric distribution systems, by integrating the fault detection and location models developed previously and integrate the developed models and algorithm into the existing energy management platform.

Industrial Partner: Unique Technical Services, LLC

Unique Technical Service (UTS) is a small business specializing in development of power electronics for hybrid vehicles and electrical grid.

Industrial Partner: ThermoLift, Inc

ThermoLift is developing a cold-climate, natural gas air-conditioner and heat pump technology that combines heating, air-conditioning, and water heating into a single appliance.

This project will focus on studying thermodynamic and kinematic performance of the Vuilleumier natural-gas heat pump that developed by ThermoLift, Inc. The advantage of the ThermoLift design is that the same device can be used for both heating and cooling. By using natural gas, the device can take off load from the electrical grid during the summer months. ThermoLift uses expertise of SBU Department of Mechanical Engineering to model kinematic performance of the machine and identify the design improvements.

The improved machine can provide a 30-50% reduction in building HVAC costs as well as associated reductions in greenhouse gas emissions.

Industial Partner: National Grid

National Grid is one of the largest investor-owned energy companies in the world - covering Massachusetts, New York, Rhode Island and the UK. The company is delivering clean energy to support our world long into the future.

The CIEES team is evaluating market and technology for distributed energy generation using gas on Long Island. The goal is to estimate impact of renewable gas on Power Production on Long Island. Distributed natural gas generation is considered a viable option for relieving grid strain in congested load pockets, such as South and North Forks of Long Island. The natural gas generators, working in tandem with renewable energy sources, offer an economic alternative to chemical energy storage in some load pockets.

The CIEES team, led by Prof. Dr. Devinder Mahajan, Director of Institute of Gas Innovation and Technology (I-GIT), identified hybrid gas sources based off-grid technologies for distributed power production. Specifically, 20kW skid-mounted systems are the optimum solution for distributed power generation

Industial Partner: Island Pyrochemical Industries Corporation

Island Group Enterprises (IGE) is a Long Island chemical company. IGE develops specialty chemicals and polymers that use renewable feedstock.

The project is focused on synthesis of ethyl cellulose, as well as its characterization and applications as energy materials. The main objective of this project to optimize the reaction conditions to control the desire quality of ethyl cellulose. To this a team of scientist from SBU Department of Chemistry set up a high-pressure research reactor. The setup is now producing pilot quantities of Ethyl Cellulose from renewable and widely accessible natural cellulose.

These materials can be used for a wide range of energy applications, including propellants for rapidly developing private space launch industry. Another example application includes the development of polymers for solar holographic device, which is an electricity generator that uses inexhaustible and sustainable solar energy.